Optics Valley’s Global Impact on Innovation & Exploration

via the Richard F. Caris Mirror Lab

Nestled beneath the University of Arizona’s football stadium, the Richard F. Caris Mirror Lab (RCML) quietly builds some of Earth’s most complex optical components. Known globally for crafting the world’s largest and most precise telescope mirrors, the lab has placed Arizona at the forefront of advanced optics and photonics, supporting applications across astronomy, defense, semiconductor manufacturing, and beyond.

At its core, the Mirror Lab represents a convergence of engineering ingenuity, materials science, and optical precision that defines the optics and photonics sectors. Its work underpins critical applications while fostering innovations that ripple through industry and academia. For more information on the Richard F. Caris Mirror Lab, visit https://mirrorlab.arizona.edu/

Welcome to Optics Valley (Tucson, AZ)

Overlooked and Untapped Engine for Arizona’s Economic Future – Tucson is known as Optics Valley, with reach across the state and reports a $4 billion economic impact from Arizona’s optics, photonics, and astronomy industries. It is estimated that 100 to 300 companies related to the field have their home in Arizona. These companies are primarily small, generating revenue of well below $75 million.

Optics Valley is the vortex of today’s tech and tomorrow’s breakthroughs. Harness it. Own it. Drive growth.

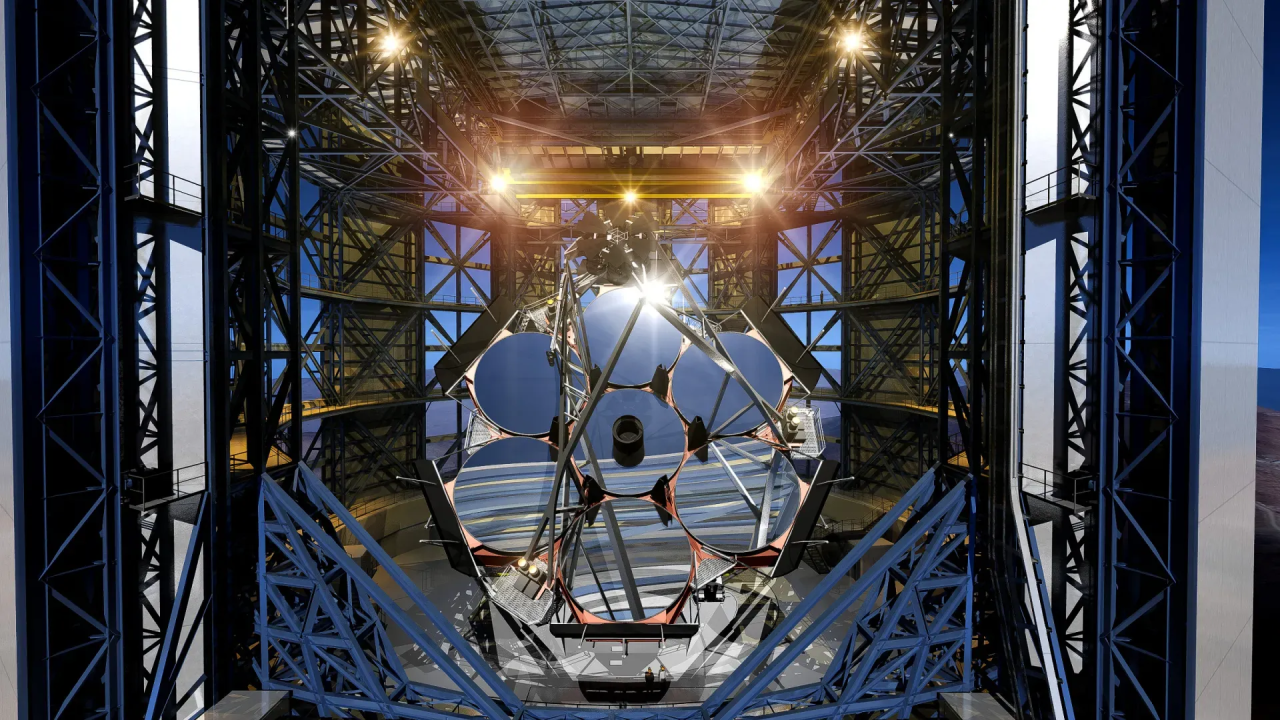

A Legacy of Giant Mirrors & Exploration

Since its inception in the 1980s under the vision of Dr. Roger Angel, the Mirror Lab has specialized in lightweight, honeycomb-structured, large-diameter mirrors. Traditional solid glass mirrors become prohibitively heavy and expensive when scaled for the next generation of telescopes. The lab solved this using spin-casting technology, where glass is melted while rotating in a mold, naturally forming a parabolic surface while cooling.

These mirrors, reaching up to 8.4 meters in diameter, are large and precisely shaped to within a fraction of a wavelength of light. They are crucial components of telescopes like the Large Binocular Telescope (LBT) on Mount Graham and the Giant Magellan Telescope (GMT) under construction in Chile, which will utilize seven of these massive mirrors to achieve unprecedented resolution and light-gathering capabilities.

Enabling Advanced Optics and Photonics Applications

While astronomy is the most direct beneficiary of the lab’s work, the technological advancements developed for producing and testing these mirrors directly support optics and photonics applications, including:

- Precision Metrology and Testing: The lab’s interferometric testing systems, including actuated secondary mirrors and computer-controlled polishing, advance high-precision surface metrology techniques critical in semiconductor lithography optics, satellite imaging, and laser systems.

- Thin-Film Coating Technologies: The reflective coatings developed and applied to these giant mirrors are relevant to industries requiring high-performance reflective surfaces, including advanced manufacturing and solar concentrators.

- Adaptive Optics Development: By supporting telescopes with advanced adaptive optics systems, the lab contributes to innovations in real-time wavefront correction, a technology now extending into biomedical imaging, defense laser systems, and free-space optical communications.

- Materials Science and Lightweighting: The honeycomb structure and spin-casting methods pioneered at RCML inspire lightweight optics strategies for aerospace and defense, where high-stability, low-weight mirrors are vital for space telescopes, drones, and surveillance systems.

Workforce and Ecosystem Impact

Arizona’s leadership in optics and photonics is strengthened by the Mirror Lab’s consistent pipeline of skilled engineers, technicians, and researchers trained in practical, high-precision optical fabrication and testing. These individuals often move into local optics and photonics companies or continue research that furthers the capabilities of the broader ecosystem, including collaborations with:

- Steward Observatory (astronomical instrumentation development)

- College of Optical Sciences (optics and photonics research and workforce development)

- Optics Valley companies specialize in manufacturing metrology, coatings, and optical systems.

This workforce connectivity is vital for building local supply chains around optics manufacturing, test equipment, and precision engineering services that support sectors from medical devices to semiconductor metrology.

The GMT: A Case Study in Optics Leadership

The lab’s flagship project, the Giant Magellan Telescope, is set to transform our understanding of the universe with seven 8.4-meter mirrors. Each mirror takes approximately four years to complete, requiring precise control of curvature, thickness, and thermal characteristics.

The GMT’s advanced optics will allow astronomers to directly image exoplanets, study the formation of the first galaxies, and probe dark matter and dark energy. But beyond astronomy, the technologies developed for the GMT’s mirrors feed back into the design and manufacturing processes for smaller but no less critical optics systems, exemplifying a technology transfer pathway from fundamental science to applied industrial optics.

Future Directions

As the demand for large-scale and high-precision optics increases globally, the Mirror Lab is exploring:

- Advanced optical metrology and AI-based surface error correction.

- New materials and lightweight composites for mirror substrates.

- Spin-off applications in defense and aerospace requiring high-performance optics under varying thermal and mechanical conditions.

- Optics integration with photonics for ground-based and satellite imaging systems.

These efforts align seamlessly with the Arizona optics and photonics cluster’s strategic goals, positioning the Mirror Lab as a leader in giant astronomical mirrors and as a driver of optical and photonic innovation across multiple industries.

Conclusion

The Richard F. Caris Mirror Lab exemplifies how visionary research infrastructure can become a cornerstone of a regional innovation economy. By building the world’s largest and most precise mirrors, the lab propels forward optics and photonics applications that impact everything from space exploration to advanced manufacturing.

Its quiet hum beneath Arizona Stadium is not just the sound of molten glass spinning into shape; it is the sound of Arizona’s optics future being formed, one precise curve at a time.

Here are Some Other Notable Space Telescopes and Planetary Missions

The University of Arizona contributes to space-based telescope and planetary mission instrumentation:

- OSIRIS-REx (Asteroid Sample Return Mission) (UA led the mission and was responsible for science operations and instrument development. Successfully returned samples from asteroid Bennu in 2023.)

- James Webb Space Telescope (JWST) (UA researchers involved in instrument teams and science operations, including mid-infrared instrument calibration.)

- Mars Missions (HiRISE on MRO) (UA operates the HiRISE camera on NASA’s Mars Reconnaissance Orbiter, providing the highest-resolution images of Mars’ surface.)

- Europa Clipper Mission (UA scientists are involved in instrument development to study Jupiter’s moon Europa for signs of habitability.)

Introductory Videos to the Giant Magellan Telescope

World’s largest telescope one step closer to completion https://www.youtube.com/watch?v=YB8Daw7atE8

Giant Magellan Telescope – “A Perfect Mirror” https://www.youtube.com/watch?v=FVVSGcfFWVc

Making the mirrors for the Giant Magellan Telescope at the University of Arizona https://www.youtube.com/watch?v=c-lBKuHqHk0

Casting a $20 Million Mirror for the World’s Largest Telescope https://www.youtube.com/watch?v=M2f4zepwcy8

Absolutely Arizona: The search for life in the universe begins under Arizona Stadium https://www.youtube.com/watch?v=Am7Tx95II88

Go Inside a Telescope Mirror Factory | To a Billionth of a Meter https://www.youtube.com/watch?v=MjUcBWYVF9s